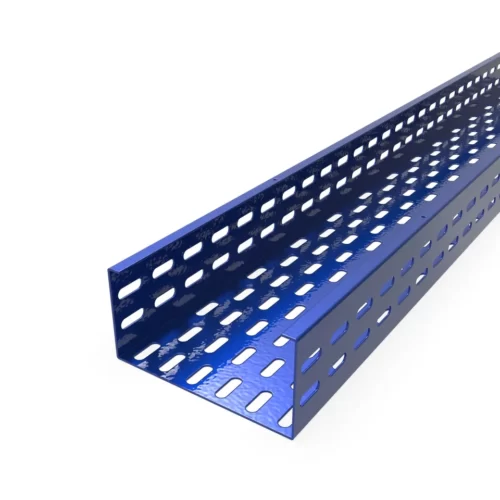

Mass Perforation Cable Tray: The Preferred Solution for Cable Management

I.Product Introduction

The Mass Perforation cable tray is a new type of cable support system.With its dense holes in the tray body,it combines features like ventilation,heat dissipation,corrosion resistance,lightweight,and high load-bearing capacity.It is widely used in various cable installation scenarios.

II.Product Features

A.Ventilation and Heat Dissipation

The dense holes significantly improve air circulation,effectively dissipating heat generated by cables during operation.This extends cable life and is especially suitable for high-density cable installations in data centers and communication stations.

B.Corrosion Resistance

Made of hot-dip galvanized material,it forms a dense zinc layer on the surface that can resist damp and corrosive environments.This reduces maintenance costs and is ideal for complex industrial settings like chemical plants and pharmaceutical factories.

C.Lightweight and High Load-Bearing

Hot-dip galvanized material is strong and durable.The cable tray itself is lightweight,making it easy to install and transport,while still having a high load-bearing capacity to meet the needs of large projects.

D.Flexible Installation

The modular design allows for quick assembly and can be flexibly combined according to actual needs.It can adapt to various installation paths,including straight lines,turns,and multi-level layouts,improving construction efficiency.

E.Aesthetic and Practical

The appearance is simple and neat,with neatly arranged holes.It is available in multiple colors to blend perfectly with the environment and enhance overall aesthetics.

III.Application Scenarios

A.Industrial Sector

Suitable for industrial environments such as chemical plants and pharmaceutical factories,where its corrosion resistance ensures the safe operation of cables.

B.Data Centers

Meets the high heat dissipation and management requirements of data centers, ensuring the safe operation of cables.

C.Commercial Buildings

Ideal for places like shopping malls and office buildings, where concealed installation is both aesthetic and practical.

D.Transportation Facilities

Adaptable to complex environments in subways and airports, with a lightweight design for easy installation and maintenance.

IV.Purchase Suggestions

A.Material

Hot-dip galvanized material is recommended for its corrosion resistance and durability.

B.Hole Size and Density

Choose the hole size and density based on cable diameter and heat dissipation needs, balancing ventilation and load-bearing capacity.

C.Certification Standards

Ensure the product meets national and industry standards and has relevant certifications to guarantee quality and performance.

V.Conclusion

The Mass Perforation cable tray, with its hot-dip galvanized material, excellent ventilation, and flexible installation, is an efficient solution for cable management. It is suitable for a variety of complex environments and provides reliable support for the safe installation and efficient management of cables.