QUALITY CONTROL

The quality of cables is related to the safety of electricity, and even related to people’s life and property safety. We mainly manage the quality of products from five aspects.

Raw Materials

The key to ensuring the quality of cable products is to guarantee the quality of its production materials.

All the cables of our company adopt high-quality oxygen-free copper and high-purity aluminum as production materials to ensure the quality of cable from the production source.

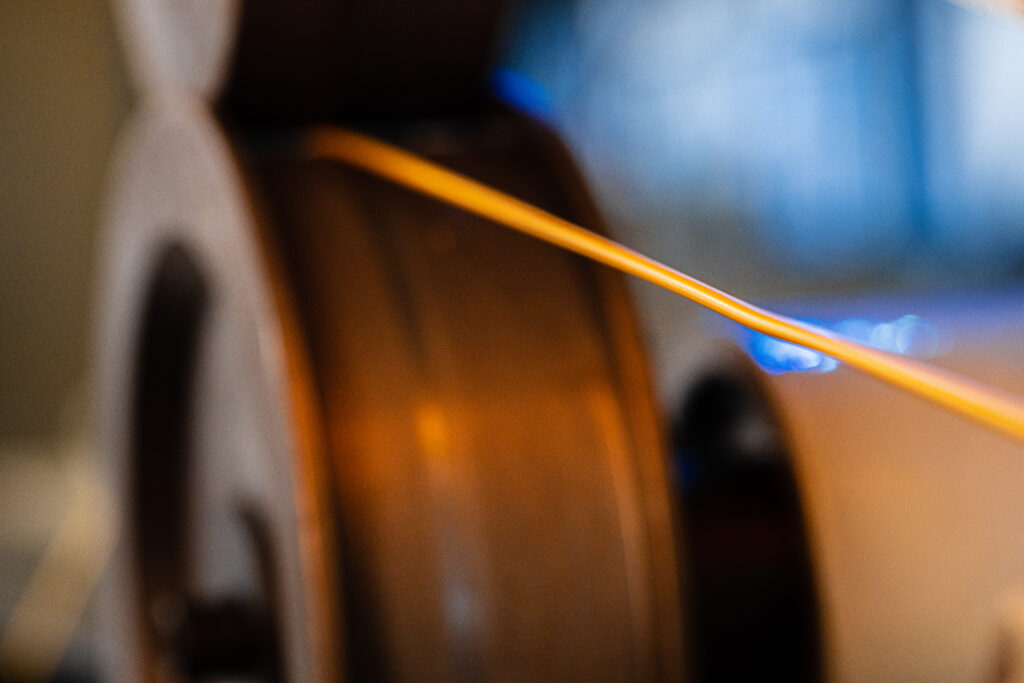

Production equipment

Advanced production equipment is another important factor to ensure product quality.

Our company adopts advanced production equipment imported from Germany to reduce production error, make conductor more uniform and insulation more reliable.

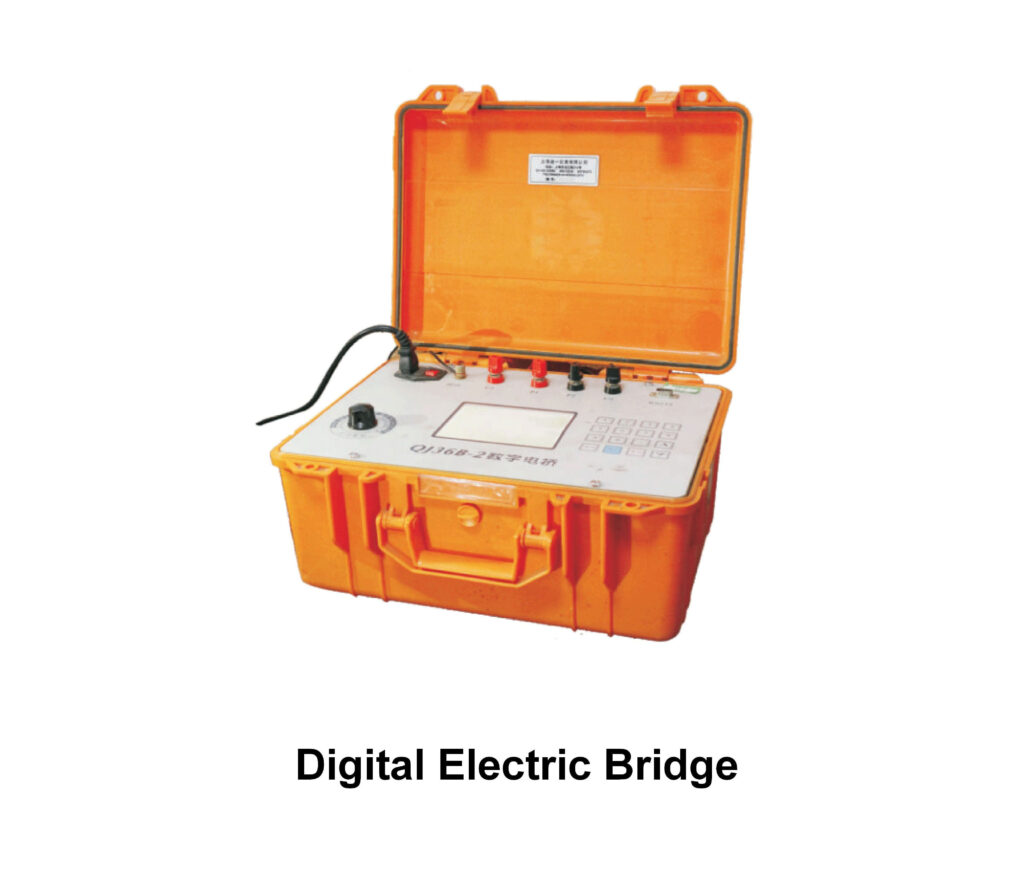

Testing

In order to ensure the quality of products, we will conduct a sampling test for each batch of low-voltage cable products, while for medium and high-voltage products, each cable must pass the test before delivery.

Our products have passed the inspection of CNAS.

Laboratory

Our company has its own laboratory, which is equipped with advanced production testing and experimental equipment.

We conduct research and development of new cable products here and also conduct sampling testing and experiments in the cable production process here.

Production Management

The management of the production process is also related to the quality of products.

We have an advanced production management system, and we have done strict control for every link of production, the executor of each process will be displayed in the production management system, and the production status and delivery date of products will also be reflected in the production management system.

Meanwhile, we have passed the ISO 9001 quality control system certification.