Cable Trunking is also named channel cable tray.

Cable trunking is an essential component in modern electrical installations, providing a secure and organized method for routing and protecting wires and cables.

The application of cable trunking varies widely, from residential and commercial buildings to industrial facilities, ensuring safety and maintaining the integrity of electrical systems. Materials for cable trunking are chosen based on the specific needs of the application; common options include PVC, known for its versatility and cost-effectiveness, and metal variants like steel or aluminum, which offer increased durability and protection against electromagnetic interference. For environments where safety is paramount, such as hospitals or data centers.

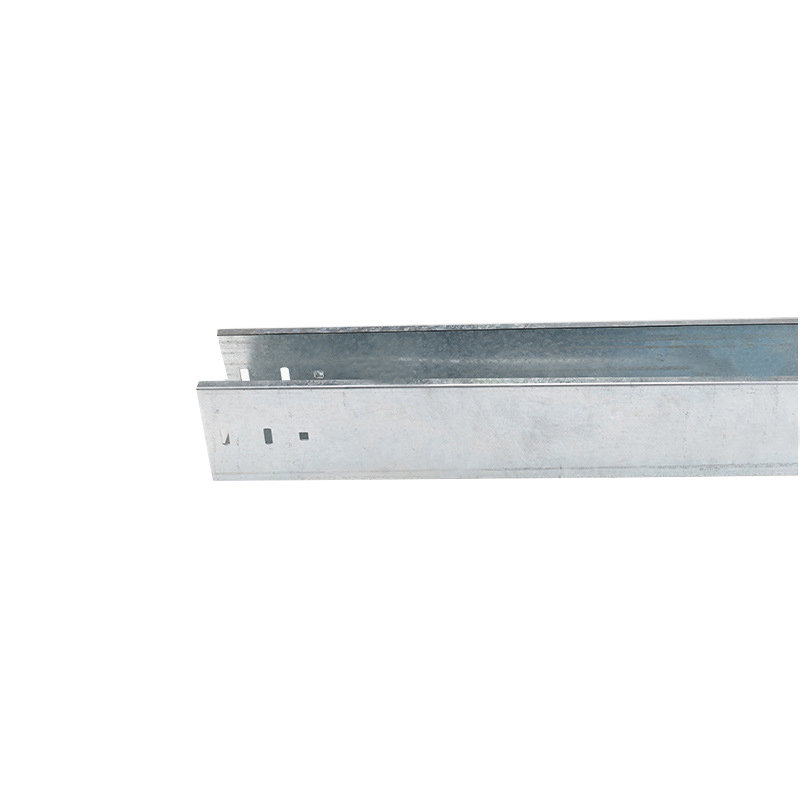

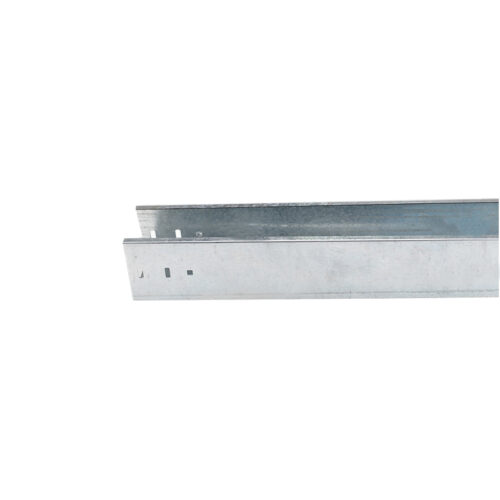

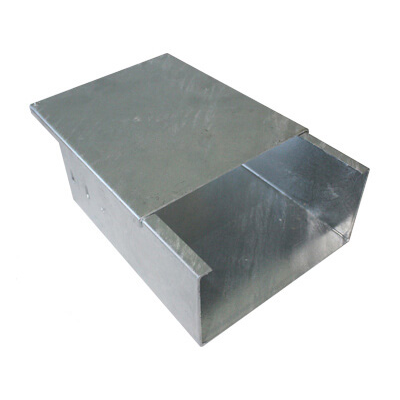

When selecting cable trunking, it’s crucial to consider factors such as the environmental conditions, the type and number of cables to be enclosed, and compliance with relevant safety standards. Cable trunking systems are an essential component in modern electrical installations, providing a secure and organized method for routing and protecting cables. A specific type of cable trunking that has gained popularity for its robustness and efficiency is the one without apertures in its body. This design ensures a higher level of protection for cables against external elements, making it an ideal choice for environments where cable integrity is paramount.

Materials like Hot-Dip Galvanized (HDG), Stainless Steel 304 (SS304), and Stainless Steel 316 (SS316) are commonly used in the manufacturing of cable trunking due to their durability and resistance to corrosion. HDG, in particular, is known for its thick zinc coating, which provides long-lasting protection against rust and degradation. SS304 and SS316 offer additional benefits, such as resistance to a wide range of chemicals and extreme temperatures, making them suitable for both indoor and outdoor applications. The application of cable trunking systems extends beyond just cable laying; they play a crucial role in protecting cables from mechanical damage, environmental factors, and electromagnetic interference.

The absence of apertures in the body of the trunking further enhances this protection, providing a continuous barrier that safeguards the cables within. In industrial settings, the use of such cable trunking systems is critical. They not only support the weight of heavy cables but also facilitate maintenance and future upgrades by allowing easy access to the cables. For projects that demand high standards of safety and reliability, choosing the right material and structure for cable trunking is a decision that significantly impacts the overall integrity of the electrical system.

In conclusion, cable trunking systems without apertures in the body, made from materials like HDG, SS304, and SS316, offer superior protection and durability for cable management solutions. Their application in various industries underscores their importance in maintaining the safety and functionality of electrical installations. As technology advances, the evolution of cable trunking systems will continue to play a pivotal role in meeting the ever-increasing demands of complex electrical networks.

Channel Cable Tray System

Galvanized HDG Cable Trunking

Available Materials: PVC, HDG, SS304, SS316, Aluminum Alloy.

Category: Channel Cable Tray System

Related products

-

Channel Cable Tray System

HDG Hot-Dip Galvanizing Channel Cable Tray System

-

Channel Cable Tray System

Long-Span Channel Cable Tray System

-

Channel Cable Tray System

Galvanized Channel Cable Tray System

-

Channel Cable Tray System

Fireproof Channel Cable Tray System