Introduction to Less Perforation Cable Tray System

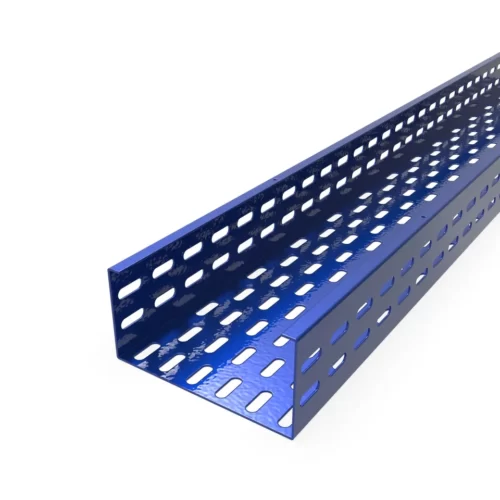

The Less Perforation Cable Tray System are an innovative and practical solution for cable management,combining the high load-bearing capacity of tray ladders with the ventilation and heat dissipation benefits of perforations.They are widely used in various industries and projects due to their excellent performance and adaptability.

Product Features

• Superior Heat Dissipation:The perforations in the tray allow for effective airflow,reducing heat buildup and extending cable life.

• High load capacity: Retaining the structural strength of tray ladders, this less-perforation cable tray system can support heavy cables.

• Ventilation and Moisture Resistance: The perforations help prevent dust accumulation and moisture buildup ,making them suitable for damp or dusty environments.

• Easy Installation and Maintenance: Simple design and flexible cable routing make installation quick and maintenance hassle-free.

• Wide Application Range: Suitable for both indoor and outdoor use,including industrial plants,data centers,chemical plants,and more.

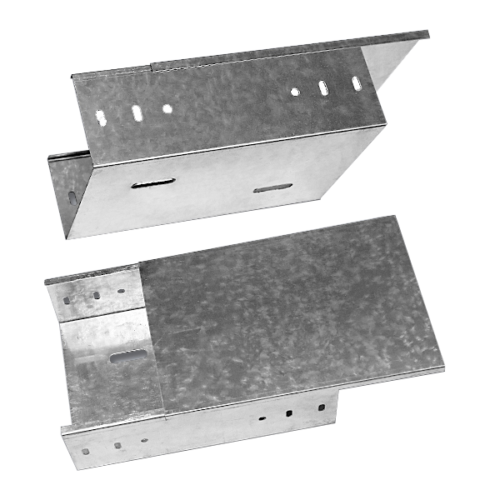

• Corrosion Resistance :Made from high-quality metal and treated with galvanizing or painting,they are durable in corrosive environments.

• Flexibility :Perforations can be customized to meet specific ventilation and cable management needs.

Product Advantages

• Safety and Reliability: Ensures stable cable operation with high load capacity and effective heat dissipation.

• Cost-Effective: Offers long-term value with reduced maintenance and operational costs.

• Adaptabilit y:Suitable for a variety of environments and cable types.

Applications

• Industrial Plants:Supports heavy cables and withstands harsh conditions.

• Data Centers:Manages complex cable layouts and ensures efficient heat dissipation.

• Chemical Plants:Provides corrosion resistance and reliable cable protection.

• Underground Parking Lots:Prevents moisture and dust accumulation,ensuring cable safety.

• Smart Buildings:Adapts to changing cable needs and supports intelligent infrastructure.

Specifications

• Width: 100 mm to 1000mm

• Height: 50 mm to 300mm

• Perforation Size: Customizable for optimal ventilation

Installation and Maintenance

• Installation:Use supports and arms to secure the ladder. Ensure proper alignment and spacing for optimal performance.

• Maintenance: Regularly inspect connections, clean dust ,and check for corrosion to ensure long-term reliability.

Less Perforation Cable Tray System are a versatile and reliable choice for modern cable management needs.