- Because the common cable is easy to appear insulation layer aging in the long-term operation process, loss of insulation performance, the service life of ordinary cable products is only about 30 years, but with the development of the economy, people’s living standards, more and more electrical equipment, electrical safety is also increasing attention.

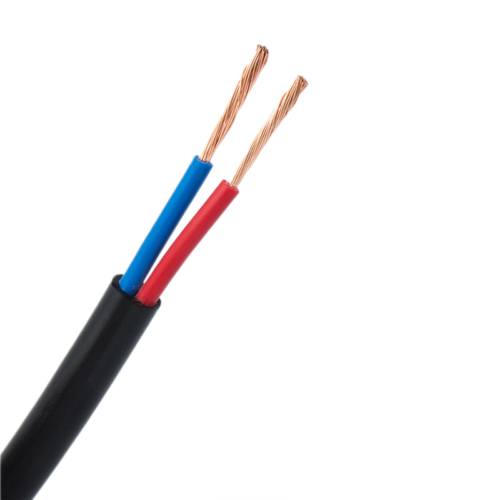

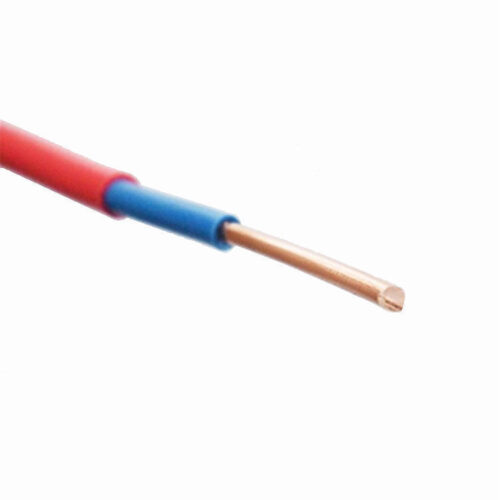

- So to meet the demand of the market, we developed the 70 – year lifespan of the low-smoke zero-halogens double insulated cable, using low-smoke zero-halogens flame-retardant radiation crosslinked polyolefine double insulation, which not only has excellent electrical insulation properties, low-smoke zero-halogen properties requirements of environmental protection, and durable can realize the cable and the service life of buildings with the same.

- This product adopts a double-layer insulation co-extrusion structure, and the inner layer is made of high-performance insulating material to ensure the electrical performance of the cable. The outer layer is made of high flame retardant insulating material to improve the flame retardant performance of the cable. Finally, the whole cable is cross-linked by irradiation to further strengthen the insulation level of the cable. This product uses low smoke halogen-free insulation material, safe and environmental protection.

- nominal voltage: 450/750V

- Long-term working temperature:

|

Insulate material |

temperature |

| cross-linking polyolefine |

105℃ |

- Short-circuit carrying temperature:

|

Insulate material |

temperature |

| cross-linking polyolefine |

250℃ |

- Cable laying temperature: above 0℃.

- The bending radius of the cable:

- The bending radius of the cable whose OD is less than 25mm shall not be less than 4OD.

- The bending radius of the cable with OD of 25mm and above shall not be less than 6OD.

- (OD: The outside diameter of the cable.)

- Ordinary cables can only pass the aging test below 80℃, while this product can pass the aging test at 160℃, and the safe use time of cables has been tested by practice.